Innovations

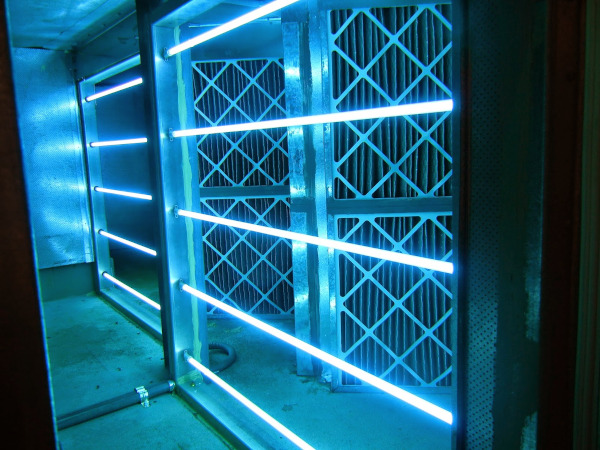

Germ Control Air Purification System

The Air purification is normally linked to filters but the fact is that the filters can only control dust particles and not the germs in the air. It came to be known that the improper moisture reduction in the cooling coil leads to high humidity levels in the room. The combination high humidity levels and lower temperature accelerate the bacterial growth and cause air contamination thereby. This contaminated air, when inhaled causes a range of health related issues, medically known as SBS – SICK BUILDING SYNDROME. So,We have introduced GERM CONTROL AIR PURIFICATION SYSTEM in all our Air Handling Units.

- Our all AHU’s will Supplied with UV-C germicidal lamps (UVGI).

- UVGI system will kill airborne bacteria, germs,Viruses and keep the air safe.

- Safeguards our customers and their employees from SBS related health issues, caused by germs in the contaminated air.

- UVGI is the simple, safe, and effective way to keep your air conditioning system clean and improve indoor air quality.

- UVGI lights for HVAC systems effectively reduce up to 99.8% of mold and other types of microbial growth inside the air system.

- Its allows the system to operate more efficiently, which saves energy and money.

Air Distribution with Jet Nozzles / Diffusers

The task of conveying conditioned air to large, sprawling spaces effectively is one of the major challenges faced by the designers of Air Distribution System. The conventional method of conveying air through large ducts with air outlets such as 4-way square diffusers or linear grilles can’t deliver the desired results in view of design limitations, and as such this method lead to wastage of power and also cause imbalance in the room temperature. We have evolved an innovative solution to address this important concern and air conditioning sprawling spaces like marriage halls, movie halls, large showrooms etc., is no longer an issue. So,We incorporate Jet Nozzles and Jet Diffusers in all our design.

- Minimize the Ducting.

- Air travel long distance both horizontally and vertically.

- Its 5 times more, compared to conventional air distribution system.

- Cooling will achieve faster.

- Extra leverage to enhance to design the interior.

- lower operating cost.

Pre-Cooling of Air-Cooled Condensers

A common problem faced by all is high power consumption of AC system during peak summer times. At high ambient temperature the compressor has to do more work to provide you the cooling. This leads to high power consumption and reduces the life cycle. To address this concern we have now come up with Pre-Cooling System for Air-Cooled Condensers. When the ambient temperature shoots beyond 35 Deg C water spray system is activated. Water particles at 32 Deg C comes in contact with the condenser and hence the condensing temperature is reduced.The same system gives extra cooling due to reduced condensing temp. Even if the ambient goes beyond 40 Deg C the water particles are still at 32 Deg C giving better performance. The power saving possible to achieve by this system could be in the range of 10 %.

- An adiabatic system for air pre-cooling during hot weather.

- Better cooling performance with increased heat transfer efficiency.

- Frequent plat tripping when the ambient temperature peaks can be avoided leading to higher system reliability and availability.

- The key advantage that this system brings is the reduction in energy costs due to the lowering of the discharge pressures. 10 Deg C reduction in air temperature can lower the power consumption by 10 – 12%.

- spray Nozzles cover across the entire coil surface area.

- Spray booster pump to give up to 6 bar G of water pressure at the nozzles, giving a fine mist.

- Adiabatic system purge/drain timer ensures that stagnation of water cannot take place.